Selecting the right roofing material represents one of the most significant investments homeowners make. Types of metal roofs have gained substantial popularity across residential and commercial properties due to their exceptional durability, energy efficiency, and aesthetic versatility. Fox Valley homeowners exploring roofing options encounter numerous metal roofing materials, each offering distinct characteristics, benefits, and considerations. Understanding these options helps property owners make informed decisions that protect their homes for decades.

Metal roofing technology has advanced considerably, moving beyond the basic corrugated panels once associated primarily with industrial buildings and agricultural structures. Modern metal roofing systems combine performance benefits with architectural appeal, complementing diverse home styles from contemporary to traditional. The variety of materials, profiles, colors, and finishes available today allows homeowners to achieve desired aesthetics while gaining metal's practical advantages.

Metal roofing technology has advanced considerably, moving beyond the basic corrugated panels once associated primarily with industrial buildings and agricultural structures. Modern metal roofing systems combine performance benefits with architectural appeal, complementing diverse home styles from contemporary to traditional. The variety of materials, profiles, colors, and finishes available today allows homeowners to achieve desired aesthetics while gaining metal's practical advantages.

Overview of Metal Roofing Materials

Why Metal Roofing Continues to Grow in Popularity

Metal roofing delivers performance characteristics that traditional roofing materials cannot match. Longevity stands among the most compelling benefits, with many metal roofs lasting 40-70 years compared to 15-30 years for asphalt. This extended lifespan eliminates repeated replacement costs and installation disruptions.Energy efficiency represents another significant advantage. Metal roofs reflect solar heat rather than absorbing it like asphalt roofs. This reflective quality reduces cooling costs by 10-25 percent during summer months. The savings accumulate substantially over the roof's lifetime, offsetting higher initial investment.

Weather resistance makes metal roofing particularly valuable in Wisconsin's challenging climate. Heavy snow slides off metal surfaces rather than accumulating. Wind resistance protects against storm damage. Fire resistant properties provide safety advantages over combustible materials. These performance characteristics create peace of mind for homeowners facing extreme weather conditions.

Quick tip: Metal roofing can often be installed directly over existing asphalt, eliminating tear-off costs and reducing landfill waste during your roofing project.

Standing Seam Metal Roofing Systems

Understanding Standing Seam Design

Standing seam roofing represents the premium option among metal roofing systems. This design features vertical panels with raised seams connecting adjacent sheets. The raised seams create distinctive parallel lines running from ridge to eave, producing clean, contemporary aesthetics.Concealed fasteners distinguish standing seam from other metal roofing types. Fasteners attach panels to the roof deck beneath the seams where adjacent panels overlap. This hidden fastening system eliminates exposed fasteners that can leak or corrode over time. The concealed attachment method contributes significantly to standing seam's superior weather resistance and longevity.

Standing seam roofs accommodate thermal expansion and contraction through clips that allow panels to move. This engineered flexibility prevents buckling or warping as temperatures fluctuate. The design proves particularly important in climates like Wisconsin's, where temperature swings reach extremes between seasons.

Benefits of Standing Seam Roofing

Standing seam roof systems deliver exceptional performance across multiple criteria. The concealed fasteners create completely watertight installations when installed correctly. No exposed penetrations mean no potential leak points from fastener failures. This design provides maximum protection against heavy rain, snow accumulation, and ice dam formation.Aesthetic appeal makes standing seam popular for residential properties. The clean lines and smooth surface create modern, sophisticated appearances. Color options span from traditional neutrals to bold contemporary shades. Factory-applied finishes resist fading far better than painted surfaces, maintaining appearance for decades.

Standing seam roofing works exceptionally well for low-slope applications. The raised seams channel water effectively even on roofs with minimal pitch. This capability expands design possibilities and suits contemporary architectural styles featuring lower roof slopes.

Wind resistance ranks among standing seam's strongest performance characteristics. The interlocking panel design and secure attachment system create continuous protection that resists uplift. Properly installed standing seam roofs handle winds exceeding 140 mph, making them excellent choices for areas prone to severe storms.

Did you know? Standing seam roofs provide ideal mounting surfaces for solar panels using clamp systems that require no roof penetrations, maintaining warranty coverage while supporting renewable energy.

Material Options for Standing Seam

Steel remains the most common material for standing seam roofing due to its strength, durability, and cost effectiveness. Galvanized steel features zinc coating that prevents rust and corrosion. Galvalume steel combines aluminum and zinc coating, offering superior corrosion resistance particularly in coastal environments or areas with high humidity.Aluminum roofing offers excellent corrosion resistance without protective coatings. The lightweight material simplifies installation and reduces structural load. Aluminum works particularly well in coastal areas where salt air accelerates steel corrosion. The material costs more than steel but eliminates rust concerns entirely.

Copper roofing represents the premium choice for standing seam installations. The distinctive appearance begins as bright metallic copper, then develops a protective patina over years of exposure. This green patina creates iconic appearances seen on historic buildings and high-end residences. Copper's exceptional durability means roofs can last 100+ years with minimal maintenance.

Zinc standing seam roofing offers another premium option. Zinc roofs develop protective patina similar to copper, though the coloration appears blue-gray rather than green. The self-healing properties of zinc mean scratches gradually disappear as patina forms. Zinc roofs last 60-100 years, making them among the longest lasting roofing materials available.

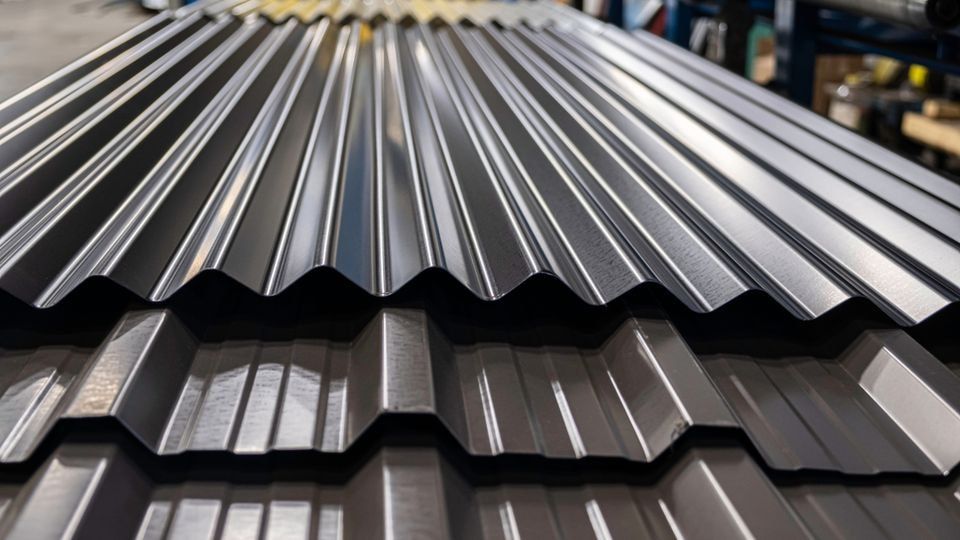

Corrugated Metal Roofing

Corrugated Metal Panel Characteristics

Corrugated metal roofing features repeating wave patterns creating alternating ridges and valleys across panel width. This classic profile represents one of the oldest types of metal roofs, with a history spanning over a century. The distinctive appearance remains popular for certain architectural styles and applications.The corrugated pattern provides structural strength through its shape. The waves act like beams, creating rigidity that allows panels to span considerable distances without sagging. This inherent strength makes corrugated metal suitable for large buildings with widely spaced supports.

Exposed fasteners attach corrugated panels directly through the material into roof decking. Fasteners with rubber washers create seals preventing water infiltration. While exposed fasteners represent potential failure points over time, modern fastener technology and proper installation techniques minimize risks.

Applications for Corrugated Metal

Corrugated metal roofing works well for agricultural buildings, workshops, and storage structures. The rustic aesthetic suits these applications where appearance takes secondary importance to durability and cost effectiveness. The material handles harsh environments and requires minimal upkeep throughout its service life.Residential applications of corrugated metal create distinctive architectural statements. Modern farmhouse styles incorporate corrugated metal roofing and siding for authentic rural character. The material suits vacation cabins, mountain retreats, and homes embracing industrial or contemporary aesthetics.

Commercial buildings use corrugated metal roofing for cost-effective weather protection. Warehouses, retail centers, and light industrial facilities benefit from corrugated metal's durability and affordable installation. The material delivers reliable performance without premium pricing.

Corrugated Metal Material Options

Steel dominates corrugated metal roofing due to favorable strength-to-cost ratio. Galvanized steel provides rust protection through zinc coating. Pre-painted steel adds color options while maintaining corrosion resistance. The material delivers decades of service when properly maintained.Aluminum corrugated roofing offers lightweight alternatives to steel. The corrosion resistant material suits coastal environments and high-humidity climates. Aluminum costs more than steel but eliminates rust concerns that affect steel in challenging environments.

Corrugated roofing in copper or zinc remains less common due to expense. However, these premium materials create stunning appearances while delivering exceptional longevity. The investment makes sense for specific architectural visions or buildings where appearance justifies premium materials.

Metal Shingles and Tile Profiles

Mimicking Traditional Roofing Materials

Metal shingles replicate the appearance of traditional roofing materials while providing metal's performance benefits. Manufacturers create profiles resembling wood shakes, slate tiles, clay tile, and dimensional asphalt shingles. Advanced stamping and coating processes create remarkably convincing appearances.These metal roofing options appeal to homeowners who want metal's advantages without departing from traditional aesthetics. Neighborhood covenants restricting roofing materials sometimes prohibit metal roofs but accept metal products mimicking approved materials. Metal shingles provide solutions in these situations.

Installation methods for metal shingles vary by product but generally resemble traditional shingle installation more than standing seam or corrugated systems. Individual shingles or small panels attach to roof decks using nails or screws. The familiar installation process allows more contractors to work with these products compared to specialized standing seam systems.

Performance Characteristics

Metal shingles deliver superior durability compared to the materials they mimic. Metal shakes will not split, crack, or rot like wood. Metal slate resists breakage that plagues natural slate. Metal tile withstands impacts that crack clay tile. These performance advantages provide peace of mind while maintaining desired appearances.Wind resistance exceeds traditional materials significantly. Interlocking designs and secure fastening prevent uplift that tears away conventional shingles. Metal shingles handle high winds that would damage or destroy asphalt, wood shakes, or clay tiles.

Fire resistant properties provide safety advantages regardless of the appearance metal shingles create. All metal roofing achieves Class A fire ratings, the highest classification. This protection benefits homeowners in wildfire-prone areas or anywhere fire safety matters.

Exposed Fastener Panels vs Concealed Fastener Systems

Understanding Fastener Panel Differences

The distinction between exposed and concealed fastener panels affects performance, appearance, longevity, and cost. Understanding these differences helps homeowners select appropriate metal roofing systems for their needs and budgets.Exposed fastener panels attach directly to roof decks with visible screws or nails penetrating the panel face. Rubber washers beneath fastener heads create seals preventing water infiltration. This straightforward attachment method simplifies installation and reduces material costs.

Concealed panels hide attachments beneath panel overlaps or within standing seams. Clips or hidden fastening systems secure panels without visible penetrations on exposed surfaces. This approach eliminates fasteners as potential failure points while creating cleaner appearances.

Performance and Maintenance Considerations

Exposed fasteners represent the primary maintenance concern for panels using this attachment method. Washers deteriorate over time from UV exposure and temperature cycling. Failed washers allow water infiltration at fastener locations. Periodic inspections and fastener replacement extend roof life but add maintenance requirements.Concealed panels eliminate this maintenance concern entirely. No exposed fasteners mean no washers to fail. The reduced maintenance requirements appeal to homeowners seeking truly low maintenance roofing solutions. The long-term cost savings from eliminated maintenance can offset higher initial investment.

Thermal movement affects exposed fastener systems more than concealed systems. Metal expands and contracts with temperature changes. Rigidly fastened panels can buckle or develop stress points. Concealed systems typically incorporate features accommodating thermal movement, preventing these problems.

Cost and Value Comparison

Exposed fastener panels cost less initially due to simpler installation and less material. The straightforward attachment process requires less specialized skill and fewer components. Homeowners with limited budgets find exposed panels provide metal roofing benefits at accessible prices.Concealed fastener systems command premium pricing reflecting their superior performance and complexity. The investment delivers benefits including enhanced weather resistance, reduced maintenance, and improved appearance. Over the roof's lifetime, the value proposition often favors concealed systems despite higher upfront costs.

Quick tip: When selecting exposed panels, choose products with high-quality fasteners and thick rubber washers—these components critically affect long-term performance and leak prevention.

Specialty Metal Roofing Materials

Copper Roofing Systems

Copper roofing represents the pinnacle of metal roofing materials in terms of appearance, longevity, and prestige. The distinctive material creates stunning roofs that become architectural focal points. Copper's natural beauty and unique aging process appeal to homeowners seeking premium roofing solutions.New copper roofing begins with bright metallic orange-brown color that gradually darkens over months of exposure. Eventually, the protective patina develops, transforming copper to its iconic blue-green color. This weathering process typically requires 15-30 years depending on climate conditions. The patina protects underlying metal from corrosion, allowing copper roofs to last centuries with minimal maintenance.

Copper roofing excels in standing seam applications where its malleability allows complex architectural details. Turrets, dormers, and decorative elements benefit from copper's workability. The material also performs well in other configurations including shingles and tiles.

Cost positions copper among the most expensive metal roofing materials. However, the investment delivers unmatched longevity and timeless beauty. Historic buildings worldwide demonstrate copper roofing's ability to protect structures for generations. For homeowners planning long-term ownership or restoring historic properties, copper often represents the right metal roof choice.

Zinc Roofs and Their Unique Properties

Zinc roofs offer many of copper's advantages at somewhat lower costs. The material develops protective patina that appears blue-gray rather than green. This weathering creates distinguished appearances that complement various architectural styles from traditional to contemporary.Self-healing properties make zinc unique among metal materials. Minor scratches gradually disappear as patina forms over damaged areas. This characteristic maintains appearance despite occasional surface damage that would permanently mar other materials.

Zinc standing seam roofing creates exceptionally long lasting roofs. Expected lifespans range from 60-100 years depending on environmental conditions and proper installation. The minimal maintenance requirements throughout this service life appeal to homeowners seeking permanent roofing solutions.

Environmental considerations favor zinc roofing. The material comes from abundant natural resources and is completely recyclable at end of service life. Zinc production requires less energy than many other metals. These factors appeal to environmentally conscious homeowners.

Aluminum Roofing Benefits

Aluminum roofing provides excellent corrosion resistance without protective coatings. The material naturally resists rust even in harsh coastal environments where salt air accelerates steel corrosion. This inherent protection eliminates concerns about coating failures exposing base metal.Lightweight characteristics distinguish aluminum from heavier steel options. The reduced weight simplifies installation and places less stress on roof structures. Older buildings or structures with limited load capacity benefit from aluminum's light weight.

Aluminum roofing works well in all metal roofing configurations including standing seam, corrugated metal, and metal shingles. Color options match those available in steel products. Factory finishes provide long-lasting color retention and weather protection.

Cost positions aluminum between steel and premium copper or zinc. The material delivers excellent value for homeowners prioritizing corrosion resistance or requiring lightweight roofing. Coastal properties especially benefit from aluminum's salt-air resistance.

Choosing the Right Metal Roof for Your Home

Architectural Style Considerations

Architectural styles influence which types of metal roofs suit specific homes. Traditional homes often benefit from metal shingles mimicking wood shakes or slate. These options provide metal's performance while respecting historic architectural character.Contemporary and modern homes pair beautifully with standing seam metal roofing. The clean lines and minimalist aesthetic complement modern design principles. Bold colors or natural metal finishes enhance contemporary architecture.

Farmhouse and rustic styles embrace corrugated metal roofing authentically. The material's agricultural heritage aligns with farmhouse aesthetics. Modern farmhouse designs often combine corrugated metal with board-and-batten siding for cohesive appearances.

Colonial and traditional styles can incorporate standing seam or metal shingles. Choosing appropriate colors and profiles ensures metal roofing complements rather than clashes with architectural details. Professional design guidance helps navigate these decisions.

Climate and Weather Factors

Wisconsin's climate demands roofing material capable of handling extreme weather conditions, heavy snow, ice, and temperature fluctuations. All metal roofing types handle these challenges better than asphalt shingles, but specific considerations affect material selection.Standing seam metal roofs excel in snow country. The smooth surface allows snow to slide off rather than accumulating. Raised seams prevent ice dam formation better than other profiles. These characteristics make standing seam particularly valuable in areas with significant snowfall.

Coastal areas or high-humidity environments benefit from aluminum or premium steel with superior corrosion resistance. Salt air and moisture accelerate corrosion on standard galvanized steel. Investing in corrosion resistant materials prevents premature deterioration in these challenging environments.

Wind-prone areas require secure attachment systems. Standing seam metal roofing with concealed fasteners provides maximum wind resistance. The continuous attachment and interlocking panels resist uplift forces that damage other roofing materials.

For comprehensive comparison of metal roofing against traditional materials, review metal roof vs shingles to understand performance differences.

Budget and Long-Term Value

Initial costs vary substantially across metal roofing types. Exposed fastener corrugated panels represent the most affordable options. Standing seam systems command mid to premium pricing. Specialty materials like copper or zinc cost significantly more than steel or aluminum.Long-term value calculations must consider lifespan, maintenance requirements, and energy savings. Premium metal roofing systems may cost twice as much initially but last three times longer than budget options. The reduced maintenance and eliminated replacement costs often justify higher investment.

Energy efficiency affects operating costs throughout the roof's life. Reflective coatings and colors reduce cooling costs. These savings accumulate over decades, improving return on investment. Energy-efficient metal roofing qualifies for tax credits in some circumstances, offsetting initial costs.

Insurance considerations sometimes favor metal roofing. Superior fire resistance and wind resistance may reduce premiums. The savings over 40-50 years contribute to overall value. Homeowners should inquire about potential insurance discounts when evaluating metal roofing options.

Installation Process and Requirements

Professional Installation Importance

Metal roofing installation requires specialized knowledge and equipment. Proper installation critically affects performance and longevity. Errors during installation can compromise even the highest quality materials, creating leaks, buckling, or premature failure.Standing seam installation demands particular expertise. Forming and seaming panels requires specialized tools. Understanding thermal movement accommodation and proper clip spacing prevents problems. These technical requirements make professional installation essential for standing seam systems.

Corrugated metal installation follows more straightforward processes but still requires attention to detail. Proper fastener placement, sealing, and overlap prevent leaks. Flashing around penetrations and transitions must be executed correctly. Experienced installers understand these requirements and complete work efficiently.

Contractor selection significantly impacts project success. Homeowners should verify licensing, insurance, and experience with specific metal roofing types. References from past customers and examples of completed projects demonstrate contractor capabilities. Choosing qualified professionals protects the substantial investment in metal roofing.

Roof Preparation and Underlayment

Proper roof deck preparation ensures metal roofing performs as designed. The deck must be sound, flat, and capable of supporting roofing materials. Damaged decking requires repair or replacement before metal installation proceeds. This preparation protects the investment in new roofing.Underlayment provides secondary weather protection beneath metal roofing. Synthetic underlayments resist tearing and provide excellent water shedding. Proper underlayment installation prevents wind-driven rain from penetrating if water somehow bypasses metal roofing panels.

Ventilation requirements affect metal roofing performance and energy efficiency. Adequate attic ventilation prevents moisture buildup and reduces cooling loads. Proper ventilation design considers roof style, climate, and home construction. Professional installers ensure ventilation systems work effectively with metal roofing.

Flashing and Detail Work

Flashing around chimneys, vents, skylights, and roof penetrations requires careful attention. These transitions represent potential leak points if improperly executed. Metal roofing systems include specific flashing components designed for their profiles.Valley flashing channels water from roof intersections. Different metal roofing types require specific valley treatments. Open valleys use metal flashing beneath panels, while closed valleys integrate panels directly. Understanding proper valley construction prevents water infiltration.

Ridge caps complete metal roofing installations along roof peaks. These components must provide weather protection while allowing ventilation. Proper ridge cap installation affects both performance and appearance. Matching colors and profiles ensure cohesive final results.

For detailed information about roof components and how they work together, review understanding the anatomy of your roof.

Maintenance and Long-Term Care

Low Maintenance Requirements

Metal roofing's low maintenance requirements represent major advantages over other roofing materials. Unlike asphalt shingles that require regular inspection and replacement, metal roofs need minimal attention throughout their service lives.Annual inspections verify fastener integrity, sealant condition, and flashing performance. These simple checks identify minor issues before they become problems. Removing debris from valleys and gutters maintains proper drainage. These minimal tasks preserve metal roofing performance for decades.

Exposed fasteners require more attention than concealed systems. Periodic fastener inspection and replacement extends roof life. The washers beneath fasteners eventually deteriorate and need replacement. This maintenance remains straightforward but adds to ownership responsibilities.

Standing seam and other concealed fastener systems need almost no maintenance. The absence of exposed fasteners eliminates the primary maintenance concern. Occasional cleaning and inspections suffice to maintain these premium systems.

Coating and Finish Durability

Factory-applied coatings on metal roofing provide long-lasting color retention and weather protection. Modern coatings resist fading far better than earlier paint systems. Premium coatings maintain appearance for 30-40 years before showing significant fading.Periodic cleaning removes dirt, pollen, and organic growth that can stain surfaces. Simple washing with mild detergent and water restores appearance. Pressure washing works for more stubborn staining, though care prevents coating damage.

Copper and zinc roofs develop patina naturally and require no coating maintenance. The weathering process creates protective layers that last indefinitely. Homeowners who prefer original metallic appearances can apply clear coatings preventing patina formation, though this approach requires periodic recoating.

Scratches and coating damage on painted metal roofing can be touched up with matching paint. Addressing damage promptly prevents corrosion from developing beneath compromised coatings. This simple maintenance preserves roof integrity and appearance.

Addressing Potential Issues

Despite exceptional durability, metal roofing can develop issues requiring attention. Fastener loosening or failure creates potential leak points. Regular inspections identify these problems before water damage occurs. Tightening or replacing fasteners represents straightforward repairs.Sealant deterioration around flashing and penetrations eventually requires attention. Resealing these areas maintains weather protection. Professional roofing contractors can perform these repairs during routine maintenance visits.

Dents from hail or falling branches affect appearance more than function. While metal roofing resists damage better than other materials, severe impacts can create visible dents. Small dents rarely affect performance, though large damage may require panel replacement for aesthetic reasons.

Corrosion protection requires occasional attention on steel roofing. Scratches exposing bare metal should be touched up promptly. Coastal environments or areas with industrial pollution accelerate corrosion, demanding more vigilant maintenance.

The Metal Roofing Alliance provides comprehensive technical information about metal roofing systems, installation standards, and performance data for homeowners and contractors.

Frequently Asked Questions

What are the main types of metal roofs available for residential properties?

The main types of metal roofs include standing seam metal roofing with concealed fasteners, corrugated metal roofing with exposed fasteners, and shingles that mimic traditional roofing materials. Standing seam systems offer premium performance and modern aesthetics. Corrugated metal provides cost-effective durability with rustic appeal. Metal shingles deliver metal's benefits while resembling wood shakes, slate, or asphalt shingles for traditional appearances.

How do standing seam metal roofs differ from corrugated metal roofing?

Standing seam metal roofs feature vertical panels with raised seams and concealed fasteners beneath panel overlaps. This design creates watertight installations with clean, contemporary appearances. Corrugated metal roofing uses wave-patterned panels attached with exposed fasteners through the material. Corrugated profiles cost less and suit agricultural or industrial aesthetics, while standing seam delivers superior weather protection and upscale appearances for residential properties.

Which metal roofing materials last the longest?

Copper roofing and zinc roofs represent the longest lasting roofing materials, with lifespans exceeding 100 years when properly installed and maintained. These premium options develop protective patina that prevents corrosion. Steel and aluminum roofing typically last 40-70 years depending on coating quality and environmental conditions. All metal materials substantially outlast asphalt shingles, which require replacement every 15-30 years.

Are exposed fastener panels or concealed fastener systems better?

Concealed fastener panels deliver superior performance through eliminated leak points and reduced maintenance requirements. The hidden attachments also create cleaner appearances. However, exposed panels cost less initially and suit applications where budget constraints matter. For residential properties and homeowners prioritizing longevity and low maintenance, concealed fastener systems represent better long-term investments despite higher upfront costs.

How does aluminum roofing compare to steel for residential applications?

Aluminum roofing offers superior corrosion resistance without protective coatings, making it ideal for coastal areas and high-humidity climates. The lightweight material simplifies installation and reduces structural loads. Steel provides greater strength and lower costs but requires protective coatings preventing rust. Both materials perform well in residential applications, with choice depending on environmental conditions, budget, and specific project requirements.

What is zinc standing seam roofing and what are its advantages?

Zinc standing seam roofing combines premium zinc material with standing seam's superior attachment system. The metal develops attractive blue-gray patina providing corrosion protection while creating distinguished appearances. Zinc's self-healing properties allow minor scratches to disappear as patina forms. These roofs last 60-100 years with minimal upkeep. The combination delivers exceptional durability and aesthetic appeal justifying premium pricing.

Can metal roofing be installed over an old roof?

Metal roofing can often be installed over existing asphalt shingle roofs, eliminating tear-off costs and reducing waste. This installation method requires adequate roof structure to support the additional weight. Building codes limit the number of roofing layers allowed. A thorough inspection determines whether installing over an old roof makes sense. Proper installation over existing roofing requires specific techniques ensuring adequate ventilation and secure attachment.

How does the installation process differ across types of metal roofs?

Standing seam installation requires specialized equipment forming panels and creating seams. The process demands expertise ensuring proper clip spacing and panel alignment. Corrugated metal installation follows more straightforward processes using standard tools. Metal shingles install similarly to traditional shingles, allowing more contractors to work with them. Complexity affects labor costs and contractor selection requirements across metal roofing types.

What makes metal roofing a cost effective choice despite higher initial costs?

Metal roofing's exceptional durability eliminates repeated replacement costs required by shorter-lived materials. A metal roof lasting 50+ years means homeowners avoid 2-3 shingle roof replacements during the same period. Energy efficiency reduces cooling costs throughout the roof's life. Minimal maintenance requirements save time and money. Insurance discounts for fire resistant and wind resistant properties add ongoing savings. These factors make metal roofing cost effective over long ownership periods.

How do I choose the right metal roof for my home's architectural style?

Traditional homes benefit from metal mimicking wood shakes or slate while providing metal's performance. Contemporary architecture pairs beautifully with standing seam metal roofing's clean lines. Farmhouse styles embrace corrugated metal roofing authentically. Consider existing architectural details, neighborhood character, and personal preferences when selecting metal roofing types. Professional design consultation helps homeowners navigate choices ensuring metal roofing complements their home's aesthetic appeal.

Conclusion

Understanding the different types of metal roofs empowers homeowners to select materials that best serve their needs, budgets, and architectural visions. From premium metal roofing with concealed fasteners to cost-effective corrugated metal panels and versatile metal shingles, each option delivers metal roofing's core benefits of exceptional durability, energy efficiency, and weather resistance.

Metal materials span from affordable galvanized steel to premium copper roofing and zinc roofs. Each material offers distinct characteristics affecting appearance, longevity, and cost. Fox Valley homeowners must consider climate demands, architectural styles, and long-term value when selecting metal roofing systems.

The choice between exposed and concealed fastener panels affects performance, maintenance, and aesthetics significantly. Standing seam metal roofs represent premium options delivering maximum weather protection and minimal maintenance. Corrugated roofing provides durable, affordable solutions for appropriate applications. Metal shingles bridge traditional aesthetics with metal's performance advantages.

Professional installation remains critical regardless of which types of metal roofs homeowners select. Proper installation process execution ensures materials perform as designed throughout their extended lifespans. The investment in quality installation protects the substantial commitment to new roofing while maximizing long-term value.

Metal roofing continues evolving with improved coatings, expanded color options, and enhanced installation systems. These advances make metal increasingly attractive for residential properties seeking roofing materials that combine beauty, performance, and longevity. Understanding available options helps homeowners select the right metal roof for their specific circumstances and enjoy decades of reliable weather protection with minimal upkeep.

Metal materials span from affordable galvanized steel to premium copper roofing and zinc roofs. Each material offers distinct characteristics affecting appearance, longevity, and cost. Fox Valley homeowners must consider climate demands, architectural styles, and long-term value when selecting metal roofing systems.

The choice between exposed and concealed fastener panels affects performance, maintenance, and aesthetics significantly. Standing seam metal roofs represent premium options delivering maximum weather protection and minimal maintenance. Corrugated roofing provides durable, affordable solutions for appropriate applications. Metal shingles bridge traditional aesthetics with metal's performance advantages.

Professional installation remains critical regardless of which types of metal roofs homeowners select. Proper installation process execution ensures materials perform as designed throughout their extended lifespans. The investment in quality installation protects the substantial commitment to new roofing while maximizing long-term value.

Metal roofing continues evolving with improved coatings, expanded color options, and enhanced installation systems. These advances make metal increasingly attractive for residential properties seeking roofing materials that combine beauty, performance, and longevity. Understanding available options helps homeowners select the right metal roof for their specific circumstances and enjoy decades of reliable weather protection with minimal upkeep.